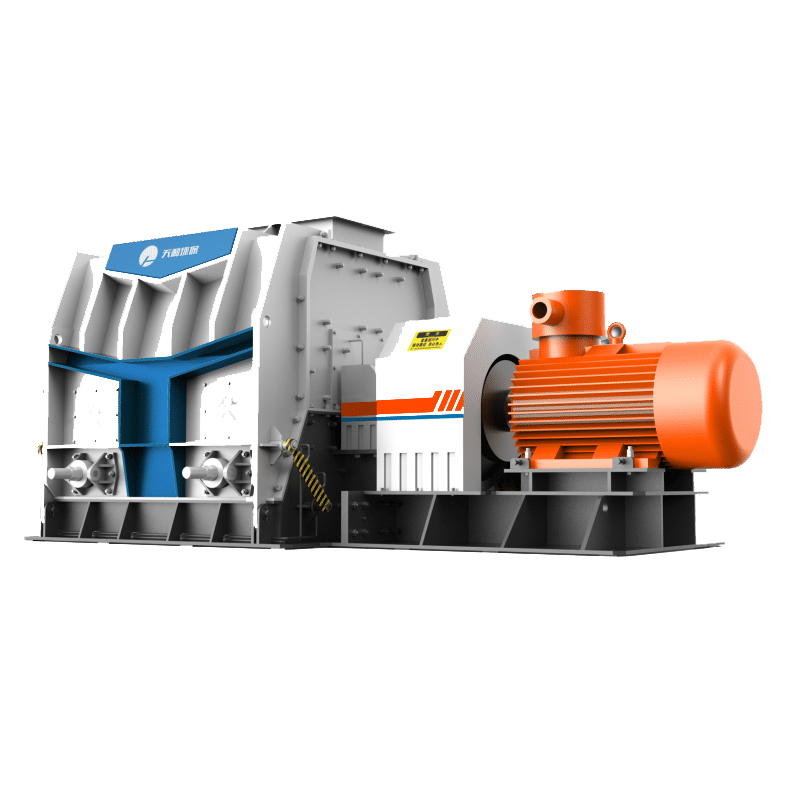

Top Quality Limestone Roller Crusher

LIMESTONE ROLLER CRUSHER

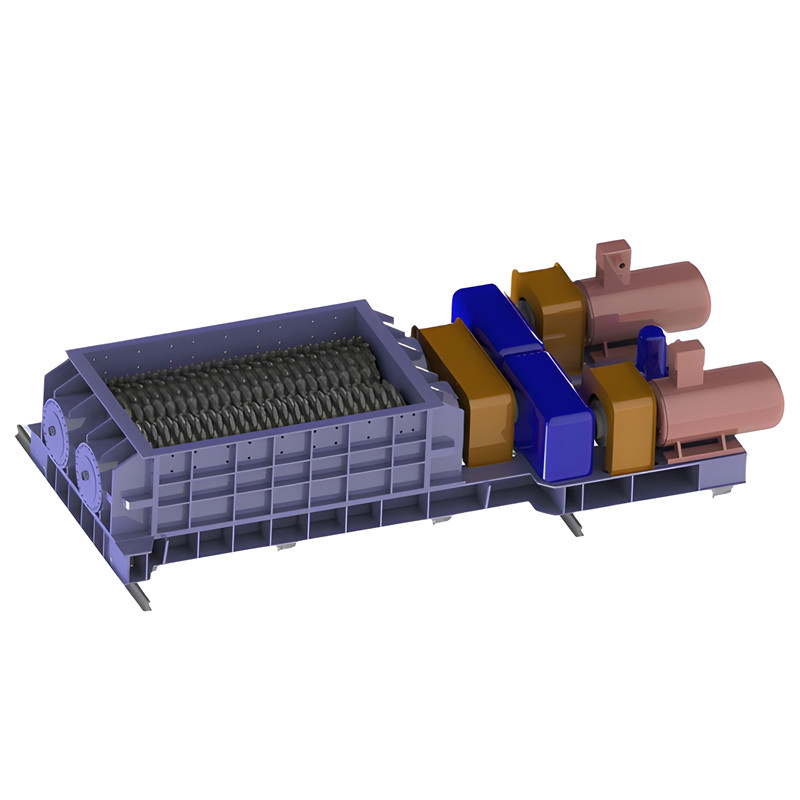

Double roller crusher adopts the crushing theory of shearing, squeezing and stretching to break the material. The biggest advantage is high lump formation rate, low over-crushing rate, and regular discharge material shape, high capacity up to 1000 tons/ hour.

Limestone is mainly used for the production of calcium carbide or quicklime after crushing. The higher lump rate and the more regular material shape, the better quality of the finished product and the higher of production efficiency.

Since 2013, Tianhe Technology purpose-designed powerful double roller sizing crusher has gradually replaced traditional secondary crushing equipment such as secondary limestone impact crusher, secondary cone crusher, secondary jaw crusher, etc. The limestone crushing sites more than 100 projects, has basically monopolized the market for secondary limestone crushing in China domestically market as well as abroad .

LIMESTONE DOUBLE ROLLER CRUSHER ADVANTAGES

Compared with traditional secondary limestone crusher,such as hammer crusher, impact crusher, jaw crusher, cone crusher etc., it has the following advantages:

|

Item |

Traditional secondary crusher |

Advanced secondary crusher |

|

|

equipment |

hammer crusher impact crusher |

jaw crusher cone crusher |

powerful double roller crusher |

|

crushing principle |

impact |

squeezing |

shearing and stretching |

|

40-90mm lump rate |

30-40% |

40%-55% |

65%-80% |

|

material shape |

Good shape, close to regular polyhedron or round |

poor shape,including a large number of long strip, sheet material |

uniform good shape and the product is close to regular polyhedron |

|

crushing efficiency |

low efficiency |

high efficiency, capacity up to 1000 tph |

|

|

discharge size adjustment |

adjustable,but difficult to operate |

adjustable,easy operate |

|

|

maintenance cost |

large amount of maintenance, high maintenance cost |

the maintenance amount is very small, the maintenance cost is low, the service life of the teeth greater that 3 million tons |

|

|

resource utilization |

low utilization rate, severe over crushing rate , resulting in a lot of resource waste |

lump rate increase at least 15%-30% |

|

|

economic benefit |

The industry of calcium carbide and quick lime production with limestone seriously requires higher material size and material shape of limestone; The traditional secondary crushing equipment with high over-crushing rate and poor material shape, which seriously affect the production benefit and sales of limestone, and produce too much over-crushing material, resulting in a serious waste of resources. |

The yield of finished limestone materials increased by more than 15%, greatly improving the utilization rate of raw materials; Material good shape, improve the quality of downstream products; Low power consumption, saving electricity cost; Small overhaul, low maintenance cost, reduce the operation cost. |

|

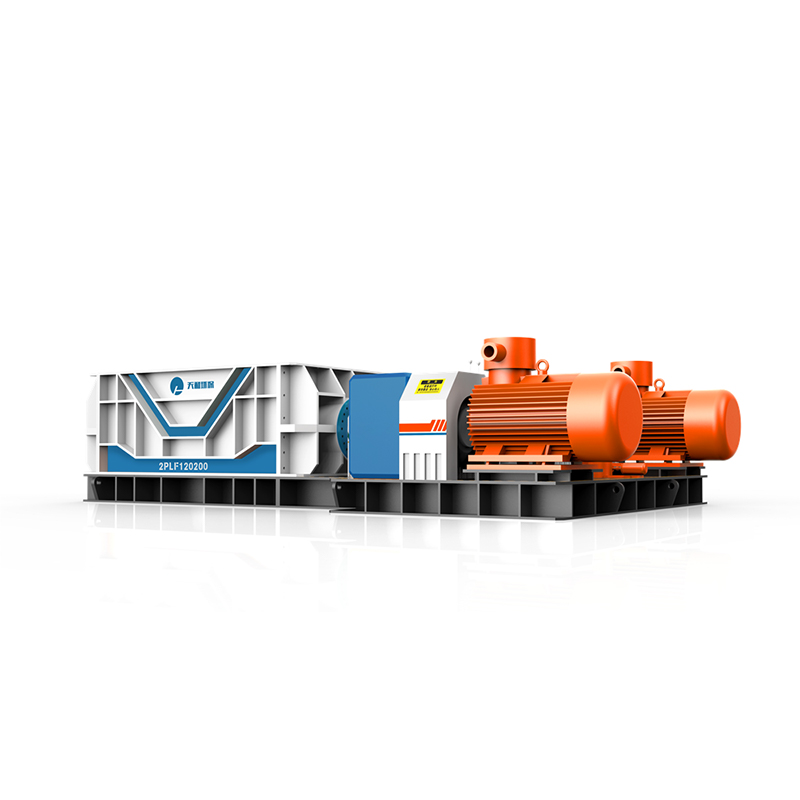

TECHNICAL DATA

|

Model |

Input Size (mm) |

Output size (mm) |

Capacity (t/h) |

Motor Power (kW) |

|

2DSKP80100 |

≤200 |

40-80/ 50-90 |

100 |

2×55 |

|

2DSKP80150 |

≤200 |

40-80/ 50-90 |

150 |

2×75 |

|

2DSKP90100 |

≤300 |

40-80/ 50-90 |

100 |

2×55 |

|

2DSKP90120 |

≤300 |

40-80/ 50-90 |

150 |

2×75 |

|

2DSKP90150 |

≤300 |

40-80/ 50-90 |

200 |

2×90 |

|

2DSKP90200 |

≤300 |

40-80/ 50-90 |

300 |

2×110 |

|

2DSKP100250 |

≤350 |

40-80/ 50-90 |

600 |

2×132 |

|

2DSKP120300 |

≤400 |

40-80/ 50-90 |

1000 |

2×160 |